Corrugated board edge crush test (ECT)

Small carton is every day countless the unsung heroes of the delivery.

Through the use of such as Edge Crush Test (ECT), such as simple Test method, the company can understand box can absorb from the biggest benefit weight stack and overall strength.

ECT is a good way to show the overall strength, make the cardboard and carton manufacturers to the formula, processing and better safeguard and improve the quality control during production testing.

In COVID - 19 lock confinement period of several weeks, the housing delivery volume surge, even online retail giants are struggling to meet demand and hire new employees.

Heard a knock at the door to receive the parcel, many people will feel less than normal and the feeling of pleasure.Small carton could safely achieve neat wide distribution of goods.

In addition to the home delivery, cardboard or the object of the frontier of public health service, to a large number of delivery in urgent need of medical equipment.

Great changes have taken place in modern production and transportation, is used to measure the test method of packaging strength also corresponding changes have taken place.Today, many shipping work is done through the box on the tray, thus to carry goods from one enterprise to another enterprise (B2B).

Test the edge of the box wall stacked strength is in the box in the process of transportation in the vertical holds its shape under the weight of the wisest and most reliable method.

From the Mullen Burst test to the Edge Crush test (ECT) test method of the continuous development

Over the years, Mullen blasting test has been the chief business of corrugated cardboard packaging grade standard.It requires the base board of minimum weight.However, because now in use in the production of corrugated board, the more recycled content, thus to find the same weight of recycled cardboard in Mullen Burst test does not always perform so well.

In spite of the fact proved that these "recycled board" box still has the very good resistance to compression and damage resistance, as shown in the edge of the fracturing test (ECT).

Mullen burst test and measurement piercing force needed for the corrugated board surface, in pounds per square inch (psi) in the form of a report, so to the corresponding rating of cardboard, for example # 275.

This test, therefore, is the need to protect the heavy, awkward items in the shape of the favour of the company, in this case, the liner shall not ruptured outward.

But, for just want to know the box can bear the weight of the biggest companies, you should firstUnderstand the whole stack of intensity- this is the Edge Crush Test of its own place, and has become a more general Test.

ECT is compressive strength of corrugated board edge measurement.Through between two rigid clamp plate edge compression on the predefined section for measurement.

Carry out the compression perpendicular to the direction of the grooves until board failures and achieve peak load.

The loading report for the force per unit width (lb/in, kN/m, etc.).When the report for ECT value (such as 44 ECT), the associated with minimum strength value, and corresponds to the pound/inch in width (lb/in).

Because the edges and corners of the box is mainly responsible for bear load, so it is a good way to show the strength of materials, making cardboard manufacturer can performThe quality controlAnd box manufacturers can choose the most suitable material and technology to produce its protective packaging

Correct ECT of corrugated board can provide rating and Mullen Burst rated the same strength, but less commonly used materials.

Less of raw materials, means lower demand for energy and less pollution, is the appropriate level ECT carton size and related functions, and combined with the more and more recycled ingredients.

Edge crust test (ECT) measurement in the extrusion of the international standard

From various standards institutions involve many international standard by the edge of the extrusion test measuring the theme of the extrusion pressure.

All over the world in the use of various methods.These can be divided into the following three categories:

- Those carefully cut rectangular specimens tested without any special treatment or changes (for example, ISO 3037 "determination of the corrugated fiberboard - edge breakage resistance - dewaxing edge method").

- Wax on the edge of the imposed force were investigated, in order to prevent the test result is affected by the "edge effect" (for example, ISO 13821 "determination of the corrugated fiberboard - resistance to lateral pressure wax - edge method").

- Those not wax was carried out on the edge of sample but its shape should be the midpoint of the length between the edge of the load significantly reduce the length of the order to cause failure along the direction away from the edge of the (FEFCO 8, for example, TAPPI T838 and TAPPI T839)

Developed for corrugated board edge crush test (ECT) test solutions

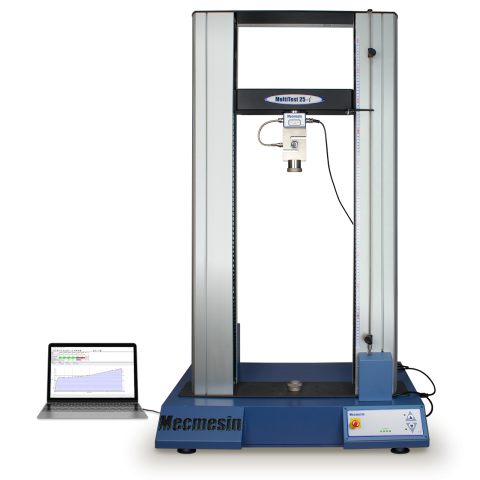

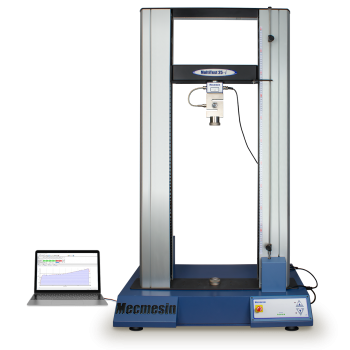

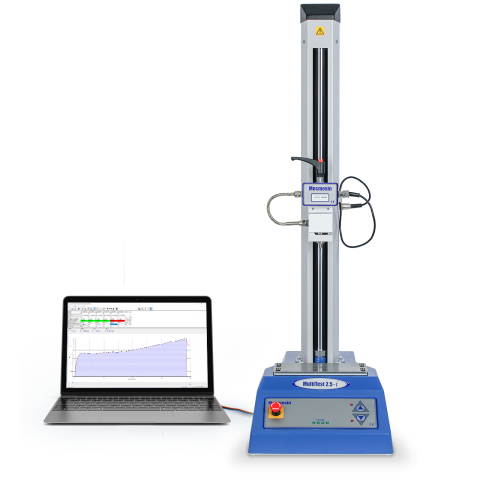

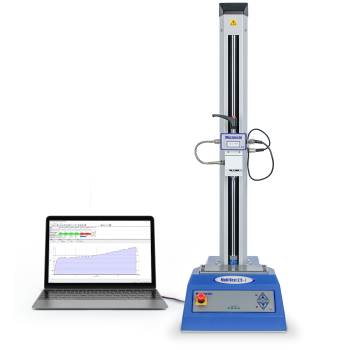

BOB体育最新下载安装Mecmesin has cooperation with manufacturers and users of corrugated board, to provide economic ECT testing system of high efficiency, and easy to use.

Controlled by the software compression tester, with rigid load column and precision weighing sensor, with a rectangular platform.Two independent guide block used to support the corrugated sample, to make it parallel to the platform.

Test program control tester at a constant speed to drop, until reach the setting load, can unload the guide block at this time.Tester then continues until the collapse of corrugated board, and the software will automatically to the unit of measure (lb/in, N/mm) "marginal" compressive strength values.

ECT compression tester desktop model can provide the capacity of 2.5 kN - 10 kN, depending on how to test the range of plate.