Compressive strength test of catalyst particle

The solution

- Software control mechanics (stretched and compressed) test system

- Since the leveling clamp

- The sample container and plunger tooling for batch test

advantage

- On the same machine test all particle geometry

- Standard software control, repeatable test a variety of materials

Test requirements

Catalysts are widely used in industrial process, including production and a matter of time is very important to the product as soon as possible.They lower the activation energy needed to a specific reaction, and often through at relatively low temperatures to speed up the reaction.

To run effectively, the catalyst needs not only excellent adsorption performance, but also requires good physical strength characteristics.The mechanical failure can lead to formation of porous aggregate small fragments and tiny particles, resulting in fluid flow obstruction, pressure drop at the ends of the reactor is not acceptable and the change of heat transfer.Therefore, to determine the mechanical strength of solid catalyst is to ensure reliable and efficient one of the key parameters of the reaction process.

Commercial catalysts have a variety of shapes, such as granular, granule, flake, spherical, annular and extrudate shape, and usually fragile, before fracture deformation is small.In the test, it puts forward the challenge, and according to the different geometric shapes and types of catalyst developed a variety of test standard.

The solution

ASTM D4179 (forming catalyst and catalyst carrier of single particle crushing strength) covers in the form of rules (such as sphere, cylinder or tablet) measurement of single particle compression "lateral pressure strength" (SCS).It can serve as radial or axial crushing test, although it should be noted that the axial crushing strength is much taller than the radial crush, and representative on behalf of the catalyst in the reactor behavior reduces.With the speed of the uniform pressure on pills, until its crushed or collapse, and record the biggest crushing strength (at the initial collapse).

ASTM D6175 (radial extrusion catalyst and catalyst carrier particles crushing strength) can measure the diameter of 1.6-3.2 mm sheet extrusion compression of catalysts "side crushing strength" (SCS), the length to diameter ratio 1:1 or higher.It only allows as radial extrusion test.At the rate of uniform pressure on pills until pill breakage or collapsed, and record every millimeter of deformation force.This is measured between 0-65 N/mm crushing strength suitable method.

When catalytic materials made from irregular particles, using single aggregate strength method could not be a meaningful test.In industrial applications, therefore, usually to bed of catalyst particles of a "large crushing strength" (BCS) test, the test by ASTM D7084 (catalyst and catalyst carrier of large crushing strength determination) covered.

ASTM D7084 covers 0.8-4.8 mm diameter of catalyst particles, such as particles.Particles contained in a cylinder of rack, and the piston.At the rate of uniform pressure on granular bed, stay for 30 seconds, then slowly release.Record led to a 1% fine powder (half by particle size of sieve particles) pressure, for grain, usually between 0.1-0.35 MPa.For larger molding material, usually between 1-3.5 MPa.

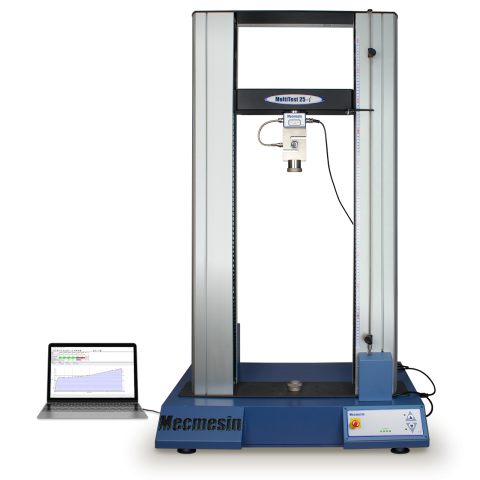

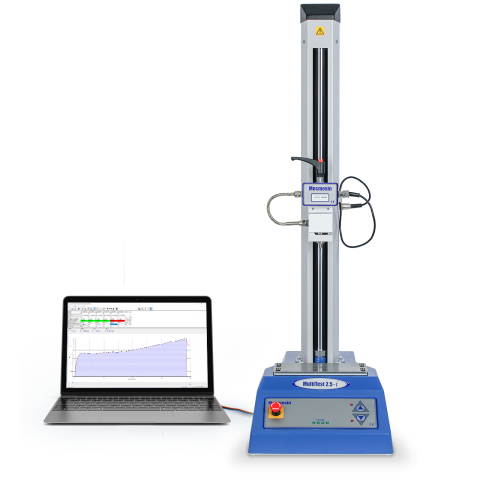

BOB体育最新下载安装Mecmesin MultiTest - I force test system is very suitable for the single grain of catalytic materials and crushing strength test as a whole.Strong test aircraft equipped with sophisticated weighing sensor, and is controlled by a powerful but easy-to-use software Emperor.At 1 kHz frequency to collect data to accurately capture the sudden rupture, and clearly drawn on the chart to show the real mechanical strength characteristics of the sample.Average crushing strength calculation by clear pass/failed to an operator instructions, and the results will be a direct export to Microsoft ™ Excel.

Complete self aligned compression steel plate can be used for single particle crushing experiment and succulometer fixture, or customized fixtures, piston and container for particles, particles and particle crushing test of the whole.

Test equipment

- MultiTest -i mechanics test system

- Since the leveling clamp

- Custom design or standard wet instrument/double extrusion tooling