The strength of the flexible packaging welding seal

The solution

- Touch screen control test bed

benefits

- Improve the quality of products

- Quantify the effective test at the scene of the production

- Just press the button, can be repeated two tests

New xt system is simple and strong enough to let us use in a production environment, but also enables us to obtain the required information.As a complete system, has the direct integration into our quality assurance system.Enable us to the information we receive with less energy than ever before, first to solve before problems affect quality.This means that we can reduce waste, improve efficiency, and can spend more time to produce our products.

William Thorley, project engineer

Reckitt Benckiser PLC

requirements

As for cosmetics, family, health care and food industry production and global brand products, for the former SSL International Reckitt Benckiser, take strict assessment and ensure the product quality is very important.It also includes the long-term integrity involves the production of packaging and product.

Use by welding seal manufacturing flexible packaging needs for validation test, to define and standardize seal strength and overall packaging manufacturing consistency.Seal may lead to poor product quality due to due to the improper production problems and deal with stress and leakage.

Reckitt Benckiser quality experts need to perform a variety of tests, including the specific forms of flexible plastic packaging is compressed load testing.This must be conducted in manufacturing unit to control in the process of verification test.

The solution

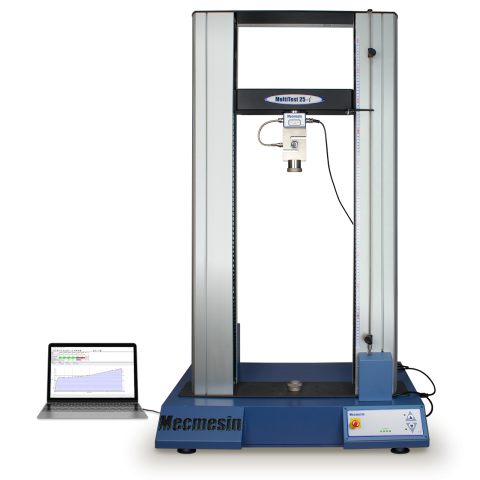

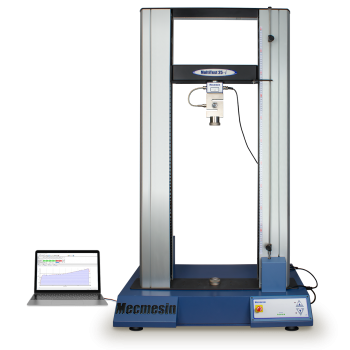

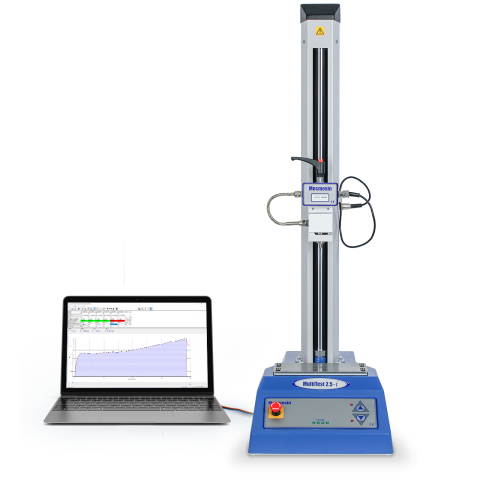

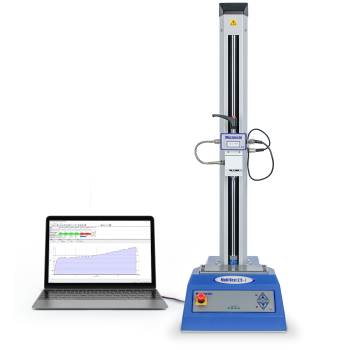

BOB体育最新下载安装Mecmesin provides four MultiTest 2.5 - xt touch screen control test system, S beam weighing sensors and specially make the compression of the probe.

After production, the sample substrate placed in the test system.Simply click on the touch screen twice, then through a user interface to choose and start the compression test.When compression probe lower, it will be a constant rate of force applied to the center of the sample, so as to gradually increase the pressure on welding of seal.

Reckitt Benckiser, under two level assessment samples, check KGF 60 and 100 KGF seal integrity.In the form of graphics on the screen "real-time" observation of sample performance, and then store it.Near to the production, can be at any given time within the scope of quality evaluation of fast and efficient multiple samples.Reckitt Benckiser, initially use MultiTest - xt to determine the benchmark of quality, by the company can now by color coding quickly identify the result of the "beyond tolerance" samples.

Test equipment

- Four with 2.5 xt MutliTest ILCS intelligent weighing sensor touch screen control test system

- Custom design compression probe fixture