Mineral wool insulation board test

solution

- The software control force test system

- Select capable of matching test load weighing sensor

- Tension clamp, the choice of the clamp

- Peeling clamp and bending it

benefits

- Standard test methods in order to realize the flexible programming environment

- Can be used for routine on-site test fixture

- On one or two machines can perform many tests

demand

Mineral wool is a kind of non-metallic inorganic materials, including stone or silica as its main ingredient.This based on the stone material is also called "asbestos" or "rock wool", is by the molten lava in the process of 1500 DHS C spun fiber formation.The material has excellent thermal insulation, fire protection and sound insulation performance of the final product is mainly used for heat insulation - usually used for buildings, vehicles and other industrial equipment, such as HVAC duct, boilers and tanks.

When made into fiber felt, with resin impregnation and curing to form the rigid plate, it is used as the low density between two thin high-density surface insulation core layer, adhesion formation of sandwich panels.Due to its high tensile strength and compressive strength and high dimensional stability, the finished sandwich panel is widely used in civil engineering project of light roof, floor and wall building structure.

The permanent load-bearing structure, including weight and external force, such as weather conditions caused by external forces;Water, ice and snow accumulation or wind.Test panel to verify the physical integrity of the load in the use of the flexibility and security of compliance is critical.

solution

Sandwich board high bearing ability is the core of mineral cotton material and the rigid connection between coverage, so test bonding integrity is very important.This can be done with proper peel test, usually at a constant Angle of 90 degrees.

Elsewhere, should design the mechanical strength test to verify the effectiveness of the load bearing function of the panel components;Bending moment in the form of axial force distribution on the two, and shear force is borne by the core layer.

To make sure that the rock wool material and the performance of the sandwich board further testing, also used a variety of other methods, including the following methods:

- At three o 'clock in the cross section of the panel and four-point bending compressive strength (ASTM C393, EN 12089)

- Tensile shear test - single sample and double sample (EN 12090)

- Tensile strength - perpendicular to the surface (EN 1607) and parallel to the surface (ASTM C297, EN 1608).

- The compressive strength (EN 826)

- A single point of compressive load (EN 12430)

- 90 degrees of adhesive peel resistance (ASTM D6862)

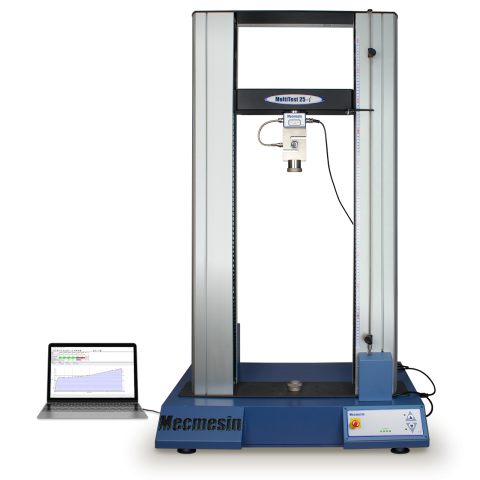

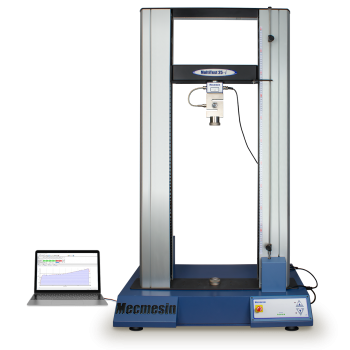

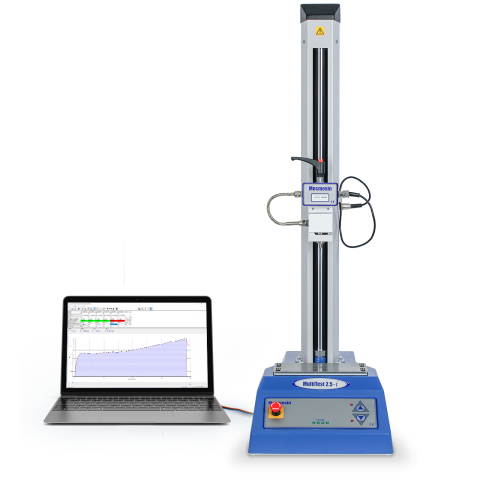

BOB体育最新下载安装Mecmesin test system is able to stretch and compression forces applied to the test samples, and a series of fixed device can also be applied, bending/bending or shear load.Single row and double row machine to provide the necessary space, the load capacity and physical test for typical test sample.

The mechanical strength of typical specifications

| features | symbol | values | The tolerance | standard |

|---|---|---|---|---|

| The density of | - | 130-200 kg/m3 | Plus or minus 10% | - |

| The compressive strength of 10% deformation | CS (10) | 60-100 kPa * | - | BS EN 826 |

| Point load strength | PL (5) | 500 or more cattle | - | BS EN 12430 |

| Perpendicular to the tensile strength | Sigma mt | Or 15 kpa | - | BS EN 1607 |

Test equipment

- Single or double column testing system

- Appropriate weighing sensor

- Peel the lift table

- Special tension controller and pressure plate

- Bending fixture