Breathing machine and auxiliary equipment component tests

The solution

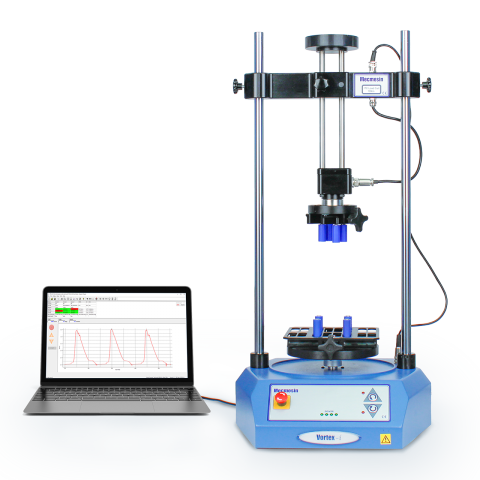

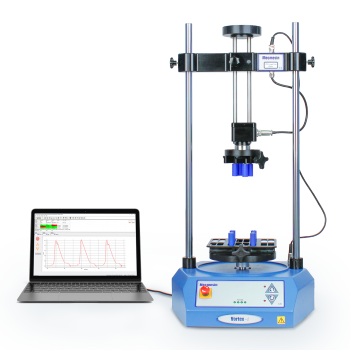

- The software control tensile and compression tester

- The software control of torque test system

- Gripper tooling

advantage

- Intuitive software, in accordance with internal clients define or international test standard

- Interchangeable jig and fixture, a test system to perform a variety of tensile and compression tests

- Test program, in the process of the programming can be used in the production line quality control inspection

- Custom reports, audit data analysis and results

Test requirements

Breathing machine (breathing apparatus) through "mechanical switch" to breathe oxygen in patients with, at the same time effective discharge of carbon dioxide in the body.Breathing apparatus is essential basic hospital auxiliary equipment, can be used for anesthesia of standard medical procedures, operation or accident and emergency first aid room, and directly or indirectly affect the diagnosis of respiratory or chronic disease.In addition, the breathing machine in many nursing homes and home care services also plays an important role.

In the respiratory tract are under the threat of epidemic disease, such as COVID - 19 coronavirus, virus attack the human respiratory system directly or show secondary conditions, such as acute respiratory distress syndrome (ARDS), breathing machine demand is growing.Many manufacturing industries have joined the mechanical breathing mechanism building, production of "open source" breathing machine (reverse engineering breathing apparatus), to make up for potential supply shortages.

Modern continuous positive airway pressure (CPAP) (CPAP) breathing machine has obtained remarkable progress.In addition, the mobility of the operation and monitoring functions of the complex electronic control.The main system includes:

- Power supply: electricity, gas supply and pressure generator.

- Oxygen control:

- Accumulator, mixer and inspiratory flow regulator

- Humidifying device

- Mechanical power and patients between subsystems

- Expiratory pressure regulator;Breathe out positive pressure (PEEP) at the end of the valve

- Monitoring: oxygen concentration, flow, pressure and volume sensor

- Security features: inlet particle, pre - bacteria and oxygen filter;Humidity/heat exchange system and alarm.

Because of the breathing machine is classified as "vital life" health care system, therefore must carry out a series of mechanical testing, to ensure that the ventilator in the execution of the multiple function as accurate and reliable.In addition, the breathing machine must be easy to use medical workers wearing protective clothing, so you must test the function of human body engineering.

The solution

Breathing machine and its spare parts (including the application in attachment) in must promote under normal use, impact, falling and mechanical stress caused by repeated operation, must have a sufficient mechanical strength.

As a result, the product/component and material testing is to ensure that the breathing mechanism and conform to the specifications of the important part.BOB体育最新下载安装Mecmesin not only provide medical equipment manufacturing and mechanical testing, and in other engineering industries of mechanics and torque test solutions with 40 years of experience, so even though rapid manufacturing of breathing machine system (RMVS) producers can also perform the appropriate quality and durability tests.

Typical of mechanics and torque test includes:

- Pumps, bearings, turbine, compressive strength, bending strength

- Pressure regulating valve, adjust and open characteristics

- Spring component: compression spring stiffness

- Touch screen: local mechanical strength

- Rotary control knob: sensation and joint feedback

- PCB welding point: fracture strength

- Crimping terminal and connector: pulling force

- Patients with loop pipe: physical pressure resistance, elongation

- 3 d printing and other composite components: mechanical strength

NIVMasks strength testThe relevant case studies.

The device under test

- Mechanics (stretched and compressed) test system

- Torque test system

- Applied to various test of standard parts, be regulatory, pneumatic clamping and quick replacement kit

- BOB体育最新下载安装Mecmesin can 3 d print custom fixture to accurate clamping components of various shapes